It’s 15 degrees colder at the top of a mountain. Might even be 20. You’re breathing heavy, a combined effect of how hard you had to work to keep speed in all that snow just to get to the lift—and the excitement at how deep the white is today. You’ve rarely seen snow in the trees like that. It started falling yesterday while you were doing laps. It piled up outside the tavern after the lifts closed and just kept dumping through the night—fine, dry powder. It’s even deeper out there in the back bowls, you notice—while trapped perspiration heat from your body filters upward as you ride the lift through the morning cold. This may be the best day you’ve ever had at this hill … if only your goggles weren’t so fogged.

Sometimes snow gear feels far more complex that it needs to be. But on days like this, with body heat and mountain cold colliding, all of that generally ignorable scientific jargon suddenly becomes relevant.

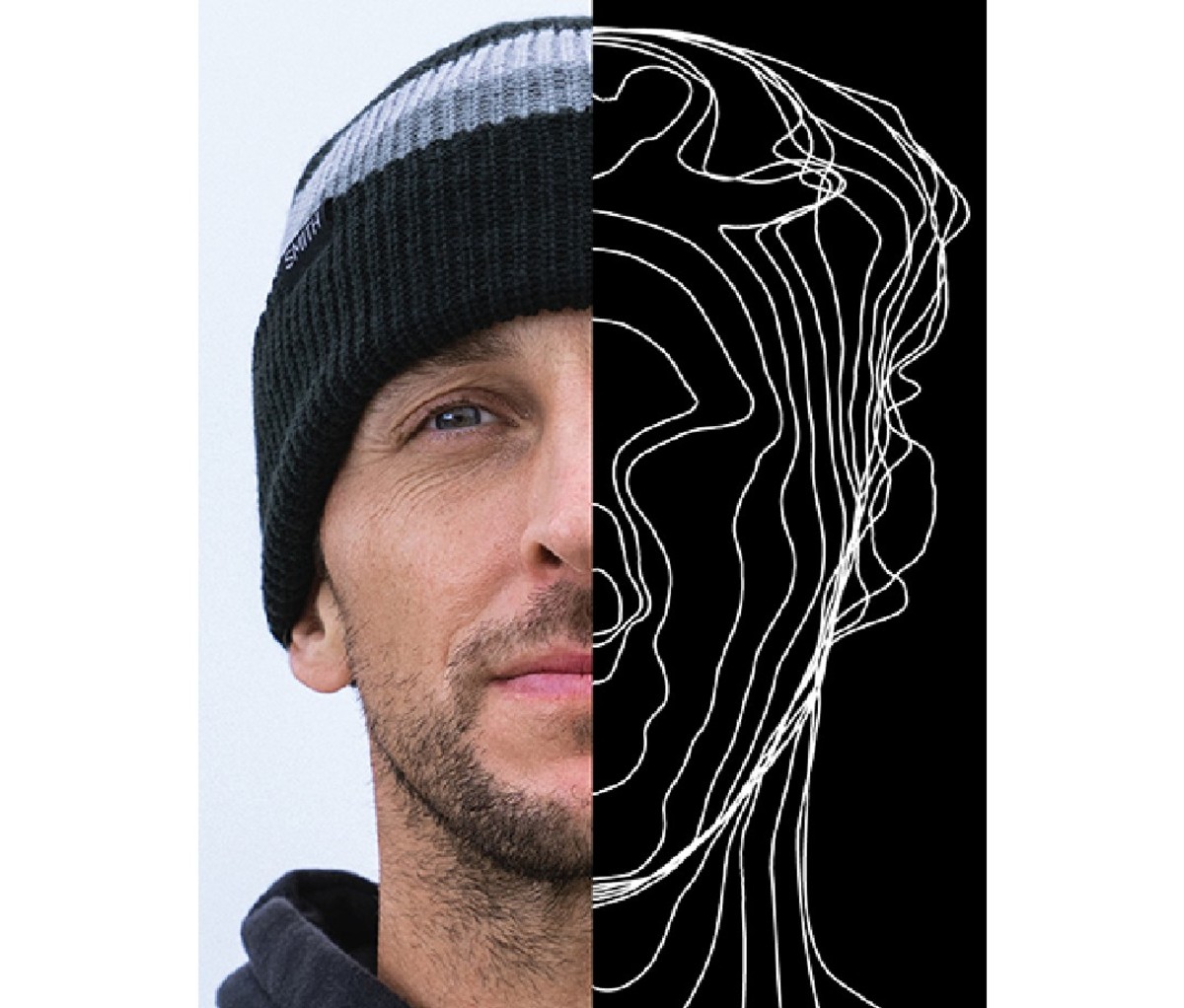

Smith, a leader in performance eyewear for nearly 60 years, has just released a snow goggle with a fit like no other—one that won’t fit anyone like it fits you. The new Smith I/O MAG Imprint 3D is the first custom snow goggle created to the exact contours and features of your face. This is the most custom eyewear you can get—exactly matching your unique facial shape and dimensions.

“Custom fit ski and snowboard boots make all the difference on the mountain, so we thought, why not tailor-make goggles too—since it’s gear that so closely interacts with the body and is also incredibly individual?” says Eric Thorsell, Senior Engineering Manager at Smith. “We’d been experimenting with creating a custom goggle, and the phenomenal feedback we received from people with more unique face shapes—larger or smaller features, asymmetrical features, and even things like broken noses—was immediately apparent and compelling for us to bring the bespoke experience to market.”

Smith, the company that invented the sealed thermal lens and breathable vent foam, utilizes a downloadable app created with Test Flight. On your phone, you follow the on-screen instruction as it scans the features of your mug. Using the patent-pending 3D Technology, an individualized 3D print of your face is sent to Smith’s U.S. factory. The team then hand-builds the face flange tailored exactly to your face with Smith’s trusted technology. You have your facially-customized goggles back in 14 days.

Until now, 12-15 mm of face foam has been used to establish fit by adjusting between the frame and facial contours. With Imprint 3D, the frame itself is tailored to match the unique shape, allowing for significantly thinner foam and reduced pressure points. Light and air leaks—what causes fogging—is thus prevented while allowing for lower strap tension and a greater field of view.

In other words, now you’re concentrating on your line instead of mucking around with your goggles.

The tech uses Smith’s proprietary ChromaPop branded lens (you get two with the I/0, for different light conditions) which provides superior clarity. Lenses can be quickly popped out and swapped through the MAG technology using strong magnets and dual locking.

While fractions of measurements and tiny tweaks may seem irrelevant with goggles, these are the little things that can make a huge difference on the hill. You may not have any “Wow, this really works!” epiphany in the doing. It’s subtler than that. But, at the end of an epic day, it will hit you. Your goggles were not an issue.

[$450; smithoptics.com]

Get it

from Men's Journal https://ift.tt/3EbGtEC

0 comments